Search

Manufacturers are rapidly embracing Industry 4.0 principles

Pepperl+Fuchs is a pioneer of industrial sensors for factory automation and an expert for explosion protection in process automation. In this interview, Aman Monga, General Manager – Sales, Pepperl+Fuchs Factory Automation, delves into challenges faced by industries and how Pepperl+Fuchs is helping them navigate through these hurdles to improve their efficiency and productivity

Service Contractors: Results Come Down to Training

From deep mines to large cement plants, the goal of the training is to ensure Martin’s customers experience maximum efficiency and productivity in their bulk handling systems

Safe conveyor equipment design

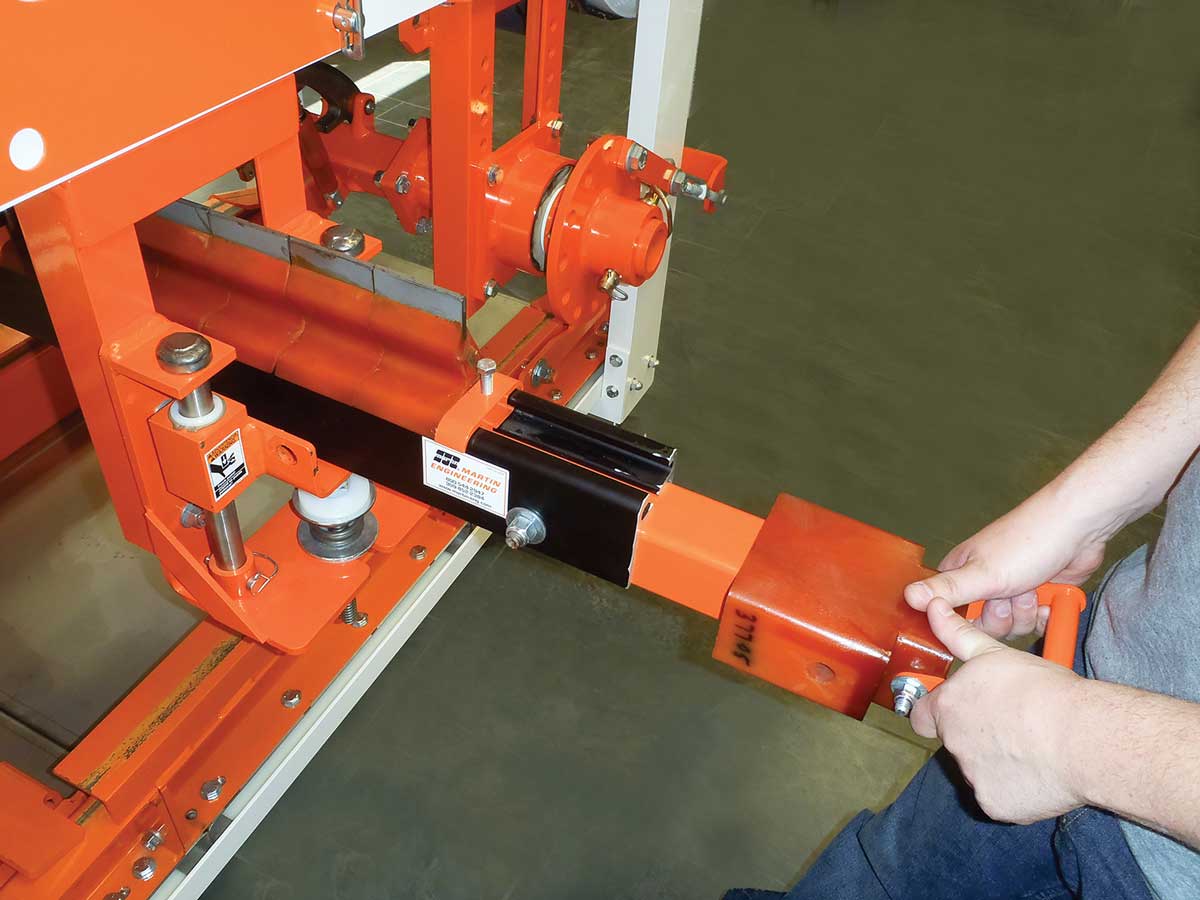

To meet the demands for greater safety and improved production, some manufacturers have introduced equipment designs that are not only engineered for safer operation and servicing but also reduced maintenance time.

Safe conveyor equipment design

To meet the demands for greater safety and improved production, some manufacturers have introduced equipment designs that are not only engineered for safer operation and servicing but also reduced maintenance time.

Martin Engineering highlights safe conveyor equipment design

Engineering safer conveyors is a long-term strategy.

The New Concrete Frontier

Contractors must adopt advanced, efficient concrete equipment to meet growing project sizes, tight deadlines, and high-strength concrete demands.

Powering Machines

Automation and industrialisation are major drivers of demand for hydraulic motors in India.

Bulk material handling equipment for steel & mining industry

Bulk material handling equipment plays a very important role in metals, mining, and related industries to ensure safe and efficient operations.

Belt Conveyor Danger Zones

Recognising the hazards is a key step toward preventing conveyor-related injuries.

High-performance high-speed doors

High-performance doors are automatic doors used for fast access between internal and external areas of buildings.

Efficient Workflow

Loading docks are a pivotal link in your supply chain. They provide the entrance for materials, parts and inventory and the exit for outbound shipments.

Effective Dust Prevention in Bulk Handling

ScrapeTec's virtually maintenance-free dust control system extends the service life of conveyor belts and reduce cleaning requirements of the entire conveyor system.

High-performance automation doors

Prime high-performance doors are designed and factory-made with German collaboration using state-of-the-art and resourceful engineering technology.

High-performance DOORS

High-speed doors are faster versions of conventional door systems such as roller doors, sectional door, PVC fabric door or roller shutter.

DECHOW auctions off premium accessories

Starting now, the experts at DECHOW Auctions based in Hamburg have been entrusted with the sale of mobile equipment from SHW Casting Technologies GmbH.

Poised for growth

Bulk material handling systems are mainly used in coal and mineral processing applications, ports for handling bulk cargo, food processing, sand, gravel, etc. Conveyor systems are the majorly used bulk material handling equipment.

Rolling innovations

Bearings for construction and mining applications have seen innovative developments in the recent times. With the construction and mining equipment market is growing, the momentum of innovation in bearings is to pick up in the coming days.

Consoveyo to participate in CeMAT Southeast Asia 2018

Consoveyo S.A. (Consoveyo), part of K?rber AG, will be exhibiting at the upcoming CeMAT Southeast Asia during May 2-6. The company?s full suite of warehouse picking solutions will be showcased at the event, along with its Automatic Storage and Retrieval Systems (ASRS).

Gearless conveyor drive for motors

ABB announced its innovative gearless conveyor drive for use on a wider range of conveyor systems. Already proven on larger motors, the newest drive is designed for medium power range motors (1 to 3 MW per motor) to make this technology economically feasible for a broader range of conveyor systems, including the use on mobile equipment in mining operations.

Cost-efficient logistics drives

In plants with many drive units, the total cost of ownership (TCO) can be reduced by up to 70 per cent through intelligent management of variants. Therefore, Nord Drivesystems has established three preferred sizes for efficient variable-frequency drives in material handling and conveyor applications.

Conveyor systems are lifeline to mining industry

Major types of conveyors used in mining include mobile/shiftable conveyors, overland belt conveyor, overland pipe conveyor, apron conveyor, reclaim feeders and sandwich belt high angle conveyor and pony belt conveyor for underground mining.

Revival on Cards?

India is witnessing an improved growth trend in coal mining, as Coal India Ltd (CIL) is aiming an output of one billion tonne by 2020. CIL has earmarked a capital investment of Rs 57,000 crore, as part of the road map for one billion tonne target, with a planned capex of Rs 8,500 crore in 2017-18.

Driving Innovation

Geared drives are essential for mechanical power transmission throughout the powertrain of equipment. With more mechanisation happening in infrastructure and construction projects, as well as material storage and haulage segments

thyssenkrupp and Siemens extend coop agreement

Due to the pressures still facing the mining industry to reduce operating costs and enhance productivity, thyssenkrupp Industrial Solutions and Siemens have decided to prolong their successful collaboration in the mining sector for another five years.

Engine and transmission assembly, and testing line

Vinar Systems is a manufacturer of conveyor systems in India, and caters to the automobile and white goods sector. It also represents Haosenread Manufacturing Co, China, which specialises in the manufacture of engine and transmission assembly and testing lines.

Bulk material handling and processing solutions

Bevcon Wayors offers new generation innovative conveying systems for bulk material handling and processing solutions for core industries like power, steel, cement mining and minerals.

The demand for TBMs has been consistently increasing.

In the first project for the Delhi Metro they used only two tunnel boring machines (TBMs), whereas in Phase 3, there are around 25 boring machines on the job, says Kapil Bhatti, Managing Director, Robbins Tunneling and Trenchless Technology India. Excerpts from the interview.

The government should form a task force team to clear all pending projects.

Bevcon is passionate about providing solutions to complex issues. We can and do provide the best possible solutions in the areas of environmental, energy conservation, cost-effective and reliable material handling solutions for the mining sector,says Y Srininvas Reddy, Managing Director, Bevcon Wayors. Excerpts from the interview.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com